Example – Marginal supply of steel

Generic product activity or name

Steel.

Synonyms

Carbon steel.

Context and background

Weidema (2014) in the case of constraints on steel production showed that the Basic Oxygen Furnace technology is the marginal steel production technology. In the following, we complete this assertion firstly by identifying the country that is the marginal supplier, and secondly by discussing scenarios of future marginal steel production (from 2020 onwards).

Presentation of example

Marginal steel supplier in 2014

Crude steel production steadily increased from 1980 to 2000 (+16%), and was subject to a large growth from 2000 to 2014 (+96%; World Steel Association, 2015a). From 2000 to 2014, the Chinese crude steel production increased by 540%, whereas the cumulated production of other countries (i.e. world excluding China) only increased by 15%. In 2014, China was both the main world producer and the main world exporter of steel (World Steel Association, 2015b). China produced 822.7 million tonnes of crude steel in 2014, the share of Chinese production over the total world production accordingly reaching 49% compared to 15% in 2000. Only a limited share of Chinese crude steel is secondary steel produced from the Electric-Arc-Furnace route (7.1% in 2010; Hasanbeigi et al., 2014).

Basic Oxygen Furnace route is the main primary production route in China, while the share of other types of primary steel production is minimal (Hasanbeigi et al., 2014). Therefore, the BOF technology is indeed the marginal steel production technology (Weidema, 2014), with China the marginal supplier.

Prospective scenarios for marginal suppliers

Life Cycle Assessment studies may require the analysis of the consequences of a decision (e.g. of a policy decision) that will be enforced later in the future. As an example, we can mention policies relative to the energy transition that will induce changes in energy infrastructures along several decades (e.g. towards a target content in renewable energies in the energy production mix in France in 2050). In the above paragraph, marginal steel supply was determined based on recent past data. Yet, “future average behavior, as well as future marginal changes, are different from those that can be predicted by extrapolating data from the recent past” (Weidema, 2016). When modelling marginal steel supply in the future (e.g. in 2030, 2040 or 2050), scenarios relative to the evolution of future steel production must be constructed and used as a basis. Two aspects must be distinguished in the determination of marginal steel supply: its technology and its geography (currently, respectively Basic Oxygen Furnace and China, as detailed in the above paragraph).

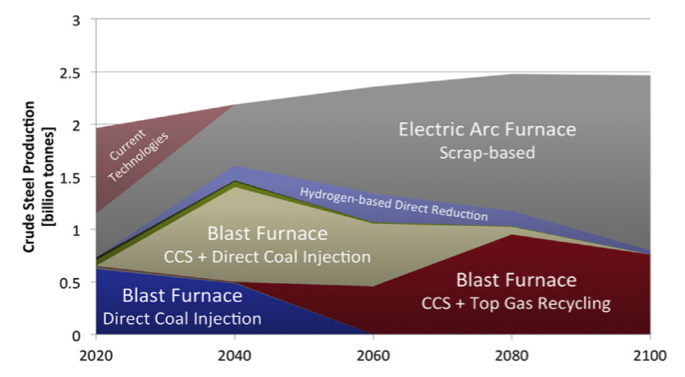

First, regarding the future marginal steel technology, the scenarios modelled by Morfeldt et al. (2015) considering assumptions on steel demand and climate ambition could be used as a basis. For example, regarding the scenario “limiting the radiative forcing up to a level of 3.5 W/m2 in any timeframe” and assuming a “demand stagnation in 2050” (Figure 2):

– from 2020 to 2040, Blast Furnace with Carbon Capture and Storage (CCS) and Direct coal injection would be the marginal technology;

– from 2040 onwards, Blast furnace with Carbon Capture and Storage and Top gas recycling would be the marginal technology.

Figure 1. “Technology competition in the binding climate target scenario […] for Demand Stagnation in 2050, based on ETSAP-TIAM results”, reproduced with kind permission (Morfeldt et al., 2015).

Moreover, choosing China as the marginal steel supplier is an option to conduct the LCA of future policy decisions, but other scenarios could also be implemented as a sensitivity analysis. Indeed it can be expected that the continuous increase in Chinese steel production may slow down in the near future. 500,000 steel industry workers are expected to be laid off as China tries to reduce overcapacity in the country’s state-run enterprises (eliminating production capacity of as much as 150 million tons of steel by 2020; CBC, 2016; Reuters, 2016). Moreover, a binding climate target may imply that regions such as China, India and South Korea (among the low-cost countries for steel production) would have difficulties meeting their domestic demand due to the high CO2 price and their dependence on fossil fuels for energy production (Morfeldt et al., 2015). The contribution of each region in the world to future global steel supply may therefore importantly depart from the current production mix. Yet, to our knowledge, no scenario currently available in the literature is sufficiently robust for the determination of future marginal suppliers.

Information sources used

Trade statistics and forecasts are available from the International Iron and Steel Institute (http://www.worldsteel.org/) and World Steel Dynamics (http://www.worldsteeldynamics.com/).

References

Reuters, 2016. China Expects 1.8 Million Coal, Steel Layoffs on Capacity Cuts. February 29, 2016 http://www.reuters.com/article/us-china-economy-employment-idUSKCN0W205X

CBC, 2016. Massive layoffs coming as China confronts its overbuilt ‘zombie economy’. Huge layoffs promised and more hard choices ahead as National People’s Congress convenes. By Saša Petricic, CBC News Posted. March, 2016. http://www.cbc.ca/news/world/china-zombie-economy-layoffs-petricic-1.3473002

Hasanbeigi, A., Jiang, Z., Price, L., 2014. Retrospective and prospective analysis of the trends of energy use in Chinese iron and steel industry. J. Clean. Prod. 74, 105–118

Morfeldt, J., Nijs, W., Silveira, S. The impact of climate targets on future steel production – an analysis based on a global energy system model, J. Clean. Prod. (2014), http://dx.doi.org/10.1016/j.jclepro.2014.04.045.

Weidema B P (2016), Example –constraints on steel production. Version: 2016-07-22 www.consequential-lca.org

Weidema B P (2016). Consequential LCA is not scenario modelling. March 13th, 2016. http://lca-net.com/blog/consequential-lca-is-not-scenario-modelling/

World Steel Association, 2015a. Crude steel production, 1980-2014. In thousand tonnes.

World Steel Association, 2015b. World Steel in figures 2015.

Author of this example

Antoine Beylot

Date

2016-06-15

How to reference this

Beylot A (2016), Example – Marginal supply of steel. www.consequential-lca.org